The Challenge: How to assign different shipping carriers and services to 2k+ orders daily while lowering costs.

The Outcome: With the help of our advanced automation engine for assigning shipping services and carriers, the client managed to organize its logistics and supply chain, without the need for employees to remember every possible scenario. This resulted in a 0% chance for human error, while also lowering related costs by 20% and decreasing average handling time by 30%.

Details: Our client is selling its brands of textile products on Amazon (Fulfilled by a merchant), eBay, and Shopify worldwide, with the help of warehouses and shipping carriers in 11 countries.

He came to us with a problem – how to easily assign shipping carriers and shipping services to 1000+ orders a day without having the need to remember each rule for assigning carriers or the need to teach someone on their team to do that and remember every possible scenario.

The goal was to automate the selection process so that the chance for human error could be reduced to 0, while also decreasing cost and handling time while maintaining high-quality service.

We had a detailed discussion about the problem of our client and decided to implement a set of smart automated actions that helped alleviate the workload from the employees and made sure that the cheapest, yet fastest possible shipping service was consistently assigned to the orders.

What does the process look like?

Previously, the employees had sticky notes flying all over the place with written rules regarding how to filter the orders and assign the proper shipping carrier and service. This resulted in countless lost man-hours, hours that could be put to better use.

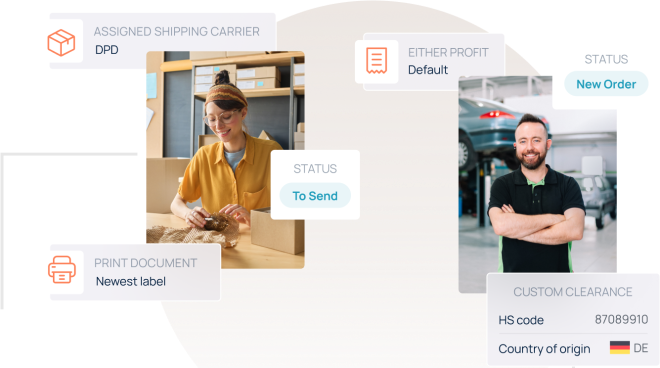

Now, Noverstock translates the business’ requirements into an automated rule, avoiding the need for employees to remember any of the specifics. The automated tool assigns the shipping services depending on the countries, weight, price, ”dangerous goods” flag, and marketplaces and could be changed at any point to include any other piece of data.

In addition to this, the customer can now easily change any part of the carrier assignment logic.

e.g. The business uses the cheapest untracked shipping services, but at some point, the deliveries are delayed or shipments get lost, which might deteriorate the health of the seller account. The business owner can contact Noverstock to implement a change to include tracked shipping service and thus make the best out of both situations. Whenever possible he makes sure to maximize its profits, and if the accounts are at risk, he quickly acts with the push of a button. All of this is immediately resolved and the Noverstock team makes sure the business needs are communicated and met on a daily basis.

This is just one example of how this rule could be used to better the operations and results of a business. It is one of our most used tools and it is unparalleled.

After implementing our automated action, the ease with which the system assigns the different shipping carriers and services completely eradicated the human error and the losses from inefficiently assigned shipping services, resulting in an immediate decrease in related costs by 20% and a decrease in average handling time by 30%.